When it comes to safeguarding your valuable equipment, understanding NEMA enclosure types can make all the difference. Imagine placing sensitive electrical components in a protective shell that shields them from dust, moisture, and harsh environmental conditions. That’s precisely what NEMA enclosures do—they serve as reliable guardians for various applications.

But what exactly are these enclosures? How do you choose the right type for your needs? Whether you’re an engineer or a DIY enthusiast, navigating the world of NEMA enclosures doesn’t have to be daunting. This guide will unravel the complexities behind different types and help you discover how they enhance durability and performance in diverse settings. Let’s dive into this essential topic!

What is NEMA Enclosure Types?

NEMA enclosure types refer to a classification system established by the National Electrical Manufacturers Association. This system categorizes enclosures based on their ability to protect electrical equipment from environmental hazards.

Each type is designated with a number and specific criteria detailing its protective qualities. For instance, some enclosures are designed for indoor use only, while others can withstand outdoor elements like rain or dust.

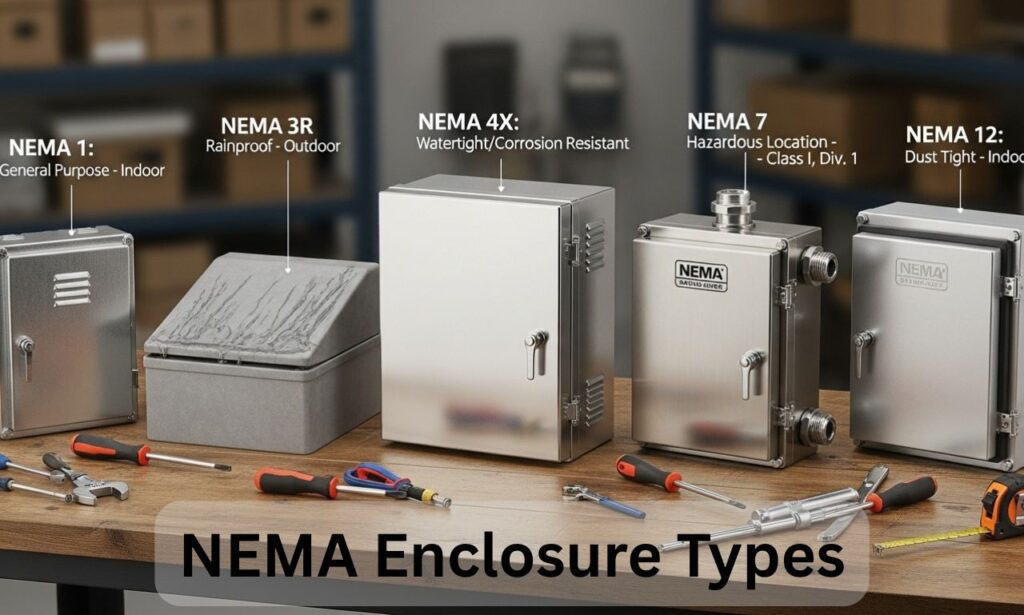

The classifications range from Type 1, which offers basic protection against dirt and light contact, to Type 4X, characterized by corrosion resistance in harsh environments.

These specifications help industries select the right enclosure suited for their unique applications. Understanding NEMA enclosure types ensures that your equipment remains safe and operational regardless of external conditions.

Understanding the Different Types of NEMA Enclosures

NEMA enclosures come in various types, each designed for specific environmental conditions. Understanding these classifications is crucial for selecting the right protection for your equipment.

For example, NEMA Type 1 enclosures are intended for indoor use only. They provide minimal protection against dust and accidental contact but are not waterproof.

On the other hand, NEMA Type 4 and 4X offer greater resistance to water and corrosion. These models are perfect for outdoor applications where moisture is a concern.

If you’re working with hazardous materials or corrosive environments, consider NEMA Type 7 or Type 9 enclosures. They cater specifically to explosion-proof settings and help contain any potential hazards.

Each type has unique characteristics tailored to different challenges, ensuring that every piece of equipment remains safe regardless of its surroundings.

Benefits of Using NEMA Enclosures for Equipment Protection

NEMA enclosures offer a robust shield for equipment against harsh conditions. Their primary function lies in protecting sensitive electronics from dust, moisture, and corrosive elements.

By utilizing these enclosures, users can significantly reduce the risk of equipment failure. This is particularly crucial in industries where reliability is paramount.

Another advantage is their versatility. Different NEMA types cater to various environments—from indoor clean rooms to outdoor installations exposed to rain and UV rays.

Cost-effectiveness also plays a role. Investing in quality enclosures minimizes repair costs and extends the lifespan of critical equipment.

Furthermore, NEMA enclosures enhance safety by preventing electrical hazards. They provide an additional layer of defense against accidental contact with live parts, ensuring compliance with industry standards.

With so many benefits at hand, choosing the right NEMA enclosure becomes essential for any operational setup that demands durability and protection.

Common Applications for NEMA Enclosures

NEMA enclosures find their way into numerous industries, safeguarding critical equipment from environmental hazards.

In manufacturing plants, these enclosures protect electrical controls and junction boxes from dust and moisture. They ensure that machinery operates smoothly, preventing costly downtime.

Telecommunications is another field where NEMA enclosure types excel. These units shield sensitive electronic components from extreme temperatures and potential physical damage.

Transport hubs also benefit—from airports to rail systems—where robust protection against weather conditions is crucial for reliable operations.

Even in the renewable energy sector, such as solar panel installations, NEMA enclosures house inverters and battery management systems safely outdoors.

From water treatment facilities to agricultural applications, the versatility of NEMA enclosures supports countless technologies while ensuring durability across diverse environments. Each application highlights the essential role these protective housings play in maintaining operational integrity.

Factors to Consider When Choosing a NEMA Enclosure

Choosing the right NEMA enclosure involves multiple considerations. The environment where your equipment will be deployed is crucial. Different locations present unique challenges, such as exposure to dust, water, or corrosive substances.

Another factor is the size of your equipment. Ensuring ample space not only for installation but also for maintenance access can save you headaches down the line.

Temperature range plays a significant role too. Some enclosures are better suited for extreme heat or cold than others.

Don’t overlook material selection either; options like fiberglass and stainless steel offer different levels of durability and protection.

Think about any specific industry regulations that may apply to your application. Compliance with these standards ensures safety and functionality in operation.

Maintenance and Care Tips for NEMA Enclosures

Regular maintenance is key to ensuring the longevity of NEMA enclosures. Start by regularly inspecting for any signs of wear or damage. Check seals and gaskets, as these are critical for maintaining protection against dust and moisture.

Cleaning should be done with care. Use a soft cloth and mild detergent to remove dirt without scratching the surface. Avoid harsh chemicals that could degrade materials over time.

Pay attention to vents and air ports; they can easily become clogged. Ensure they remain clear to allow proper airflow, which helps prevent overheating.

Consider periodic testing of enclosure integrity, especially in demanding environments. A proactive approach will help you spot issues before they become major problems, keeping your equipment safe and secure from environmental hazards.

Conclusion

Choosing the right NEMA Enclosure Types is crucial for safeguarding your equipment. The various types of enclosures offer solutions tailored to specific environmental conditions and operational needs. By understanding their classifications, benefits, and appropriate applications, you can make informed decisions that enhance the longevity and reliability of your machinery.

Regular maintenance will also play a significant role in ensuring these enclosures perform optimally over time. Whether you’re protecting sensitive electronics or rugged industrial devices, investing in quality NEMA enclosures can make all the difference in performance and safety. Make sure to consider all factors carefully to select the most suitable option for your unique situation. Protecting your equipment never goes out of style; with the right knowledge at hand, it becomes an achievable goal.